Troubleshooting advanced laptop motherboard failures is a skill that separates the hobbyist from the professional. 🎓

When a laptop presents with “no power,” “no boot,” or intermittent shutdown issues, the problem often defies simple component swapping. 🛑

Unlike desktop motherboards, where components are often modular and easier to access, laptop Printed Circuit Boards (PCBs) are marvels of high-density integration. 🏙️

This density makes diagnosis and repair a specialized field requiring patience and precision. 🔬

Effective troubleshooting here requires more than just a screwdriver; it demands a deep understanding of power delivery systems and signal logic. 🧠

You must understand how electricity flows from the DC jack to the CPU and every component in between. ⚡

It involves component-level diagnostics, often working with parts smaller than a grain of rice. 🍚

This article outlines a systematic, professional approach to diagnosing these complex faults. 📋

We will move beyond the basics of RAM swapping and dive into voltage rails, short detection, and BIOS integrity. 🚀

I. The Power-On Sequence: A Symphony of Signals 🎵

To fix a motherboard, you must first understand how it wakes up. 🌅

A laptop’s power-on sequence is a complex, choreographed series of events. 💃

Failures rarely happen randomly; they usually occur at specific stages in this sequence. 📉

By identifying which stage fails, you can narrow down the culprit significantly. 🎯

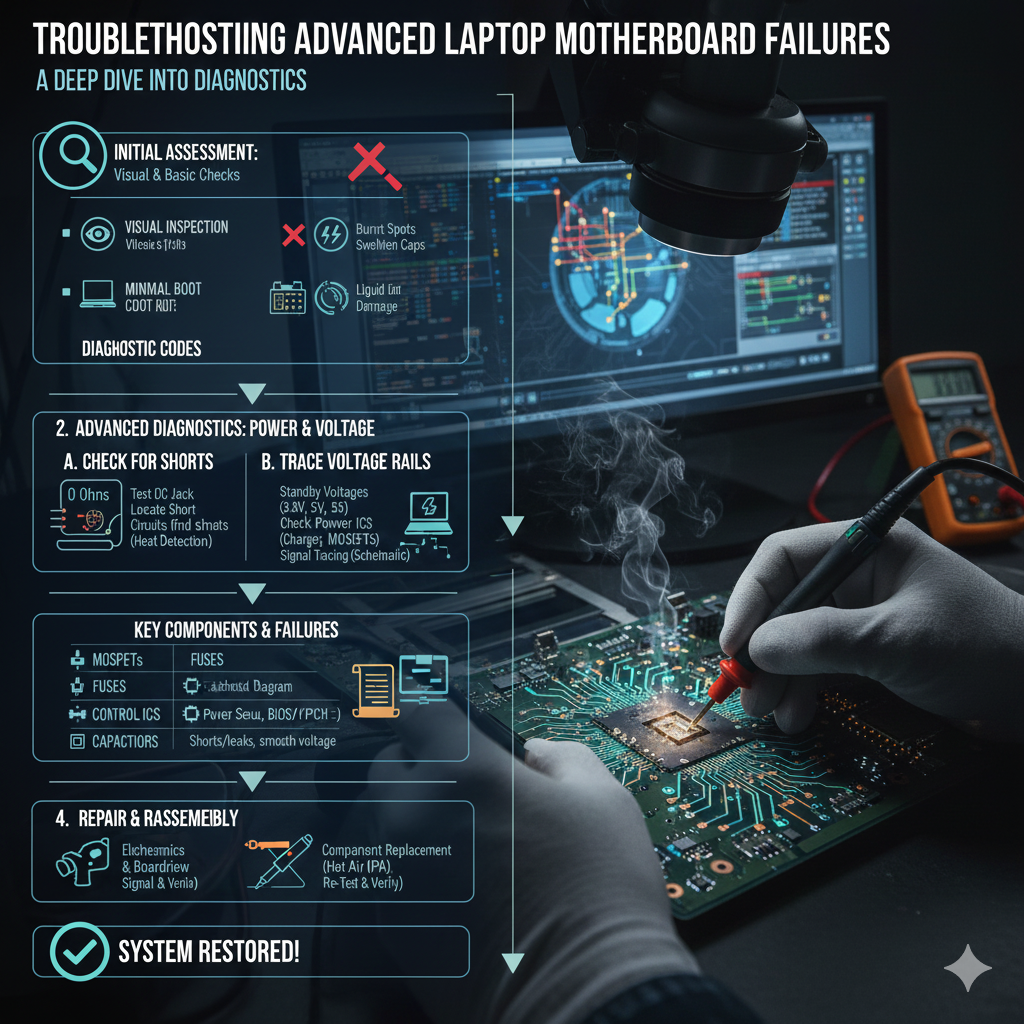

A. Initial Checks and Visual Inspection 👀

Before you even touch a multimeter, your eyes are your best tool. 👁️

Start with the basics of external power verification. 🔌

Verify that your power adapter is supplying the correct voltage and that the DC-in jack on the motherboard is physically intact. 🧱

Next, perform a rigorous visual inspection under magnification. 🔍

Look for the obvious signs of catastrophic failure. 💥

Liquid damage is a primary cause of complex failures and often leaves tell-tale signs like green or white corrosion. 💧

Even a single drop of liquid in the wrong place can bridge connections and destroy sensitive ICs. ☠️

Look for burnt components, particularly MOSFETs near the power input, which often fail spectacularly. 🔥

Bulging capacitors or discolored areas on the PCB are also red flags indicating excessive heat. 🚩

For a deeper understanding of common failure points, check out this article by Lapserve on Top 5 Reasons for your Laptop Motherboard Malfunctions. 🔗

B. The Three Stages of Power Delivery ⚡

Advanced diagnosis focuses heavily on the power rails. Hz

These rails are regulated by complex Power Management Integrated Circuits (PMICs) and orchestrated by the Super I/O (SIO) chip. 🤖

Understanding these three stages is critical for isolating the fault. 👇

| Stage | Description | Key Voltage Rails to Check | Diagnostic Tool |

|---|---|---|---|

| Stage 1: Always-On Power | Power rails that are active as soon as the adapter is connected. | 3V/5V Always-On (LDO): Essential for the SIO chip and BIOS. | Multimeter (DC Voltage Mode) |

| Stage 2: Standby Power | Power rails activated when the power button is pressed, waking the SIO. | VCC_CORE, VCC_GFX: Low-voltage rails for the CPU/GPU standby. | Oscilloscope (for ripple/noise) |

| Stage 3: Main Power | All main power rails are activated, leading to the CPU/PCH receiving power. | VCORE, VRAM, VPP: High-current rails for the main components. | Thermal Camera (to detect shorts) |

II. Component-Level Fault Isolation 🕵️♂️

Once you have identified a missing voltage rail, the real detective work begins. 🕵️♀️

Is the rail missing because the controller is dead, or because there is a short circuit pulling it to ground? 🤔

A. Short Circuit Detection and The “Voltage Injection” Method 💉

Finding a short circuit on a board with thousands of components can feel like finding a needle in a haystack. 🌾

First, use the resistance measurement mode on your multimeter. Ω

With all power removed, measure the resistance to ground on the suspected faulty rail. 📉

A very low resistance (near 0 Ω) confirms a hard short circuit. 🚫

However, telling which component is shorted is impossible with just a multimeter because they are all connected in parallel. 🤷

This is where Voltage Injection (or Current Injection) becomes the technician’s secret weapon. ⚔️

The concept is simple but must be executed with extreme care. ⚠️

You inject a low voltage into the shorted rail using a bench power supply. 🔌

The voltage must be lower than the rail’s operating voltage (e.g., 1V for a 3V rail) to avoid damaging connected chips. 🛡️

You then limit the current (e.g., to 1 or 2 Amps). ⚡

Physics dictates that the current will flow through the path of least resistance—the shorted component. 🌊

This current flow generates heat. 🔥

Using a thermal camera, or even your finger (carefully!), you can find the component that is glowing hot. 🌡️

Common culprits include multilayer ceramic capacitors (MLCCs) which crack and short internally, or power MOSFETs. 🧱

For more discussion on these diagnostic steps, check out this forum thread on Tom’s Guide regarding Motherboard Diagnosis. 🗣️

https://youtu.be/L4dJjMnbDls

B. BIOS and Firmware Corruption 💾

Sometimes, the hardware is physically fine, but the “brain” is confused. 😵

A “no boot” or constant “power cycling” issue without a detectable hardware short often points to the BIOS. 💻

The Basic Input/Output System (BIOS) initiates the hardware. 🚀

If the firmware code in the SPI flash chip is corrupted, the system may power on but fail to initiate the POST (Power-On Self-Test) sequence. 🛑

Diagnosing this involves observing the behavior of the status LEDs or using a POST card. 🚥

The repair requires a specialized tool known as a generic programmer (like an EEPROM programmer). 📠

You must carefully desolder the BIOS chip, read it, erase it, and flash a known good firmware dump onto it. 💾

A successful BIOS flash can instantly bring a seemingly dead laptop back to life. 🌱

If you are new to electronics repair, iFixit’s Laptop Repair hub is an excellent place to start learning the basics before attempting these advanced fixes. 🛠️

C. PCH and CPU Failure: The Heavy Hitters 🏋️

In modern laptops, the Platform Controller Hub (PCH) and the CPU are often integrated into a single BGA (Ball Grid Array) package. 📦

These complex chips can fail due to overheating, manufacturing defects, or power surges. ⚡

Diagnosis is tricky; the system might pass the initial power-on checks (Stage 1 and 2) but hang indefinitely before the display turns on. 🕰️

Measuring the resistance of the data lines going to USB ports can sometimes reveal a dead PCH, as these lines go directly to the silicon. 📏

Repairing this is the highest tier of motherboard repair. 🏆

It requires expensive BGA rework stations to melt the hundreds of tiny solder balls underneath the chip to replace it. 🏗️

This is a highly specialized procedure that is often not economical for older machines. 💸

For detailed technical discussions on BGA rework, specialized forums like EEVblog Repair Forum are invaluable resources. 🌐

https://youtu.be/J63dXXKq0aE

III. Essential Tools for the Advanced Technician 🧰

To perform these repairs, your toolkit needs an upgrade. 🆙

A standard soldering iron is just the beginning. 🌋

You need a high-quality Hot Air Rework Station to safely remove multi-pin ICs and MOSFETs without damaging the pads. 🌬️

A DC Bench Power Supply is non-negotiable for performing voltage injection and monitoring current draw during the boot sequence. 📟

A Digital Microscope is essential for inspecting solder joints that are invisible to the naked eye. 🔬

Finally, a good quality multimeter with fast continuity response makes tracing circuits significantly less frustrating. ⚡

Investing in quality tools pays for itself by preventing accidental damage to customer devices. 💰

For guidance on selecting the right test equipment, Fluke’s educational resources offer professional insights. 📚

Conclusion 🏁

Advanced laptop motherboard troubleshooting is a meticulous, logical process. 🧠

It requires moving from a macro-level visual inspection to micro-level voltage and resistance analysis. 🔎

By systematically checking the power-on sequence and effectively isolating short circuits, technicians can perform component-level repairs. 🛠️

This not only saves the motherboard from being e-waste but is also a highly rewarding technical challenge. ♻️

Whether it is a blown capacitor or a corrupted BIOS, every “dead” laptop tells a story waiting to be decoded. 📖

With the right tools and knowledge, you can be the one to rewrite the ending. ✍️