The integrity of a Printed Circuit Board (PCB) is the foundation of any modern electronic device. 🏛️

These boards are the nervous system of electronics, routing signals and power to where they are needed most. ⚡

A broken or damaged trace—the thin copper pathways that conduct electricity across the board—can be disastrous. 💥

It can lead to frustrating intermittent failures, strange device behavior, or a complete system shutdown. 🛑

While it might seem like a death sentence for a device, repairing these microscopic faults is entirely possible. 🛠️

It is a skill that marries art and science, requiring steady hands, precision tools, and a methodical approach. 🔬

Mastering trace repair can save expensive industrial equipment or beloved vintage electronics from the landfill. ♻️

This article outlines the essential techniques, tools, and best practices for successfully restoring continuity to a damaged PCB trace. 📚

I. Understanding Why Traces Fail 🤔

Before diving into the repair, it helps to understand why traces break in the first place. 🧐

Often, the damage is physical. 🔨

A dropped device can cause the PCB to flex, cracking traces near rigid components like heavy inductors or connectors. 📉

Other times, it is accidental damage during a previous repair attempt. 😓

A slip of a screwdriver or overheating a pad during desoldering can easily lift or sever a delicate track. 🔥

Corrosion is another major culprit, especially in devices exposed to moisture or leaking batteries. 💧

The corrosion eats away at the copper until the connection is severed. 🧪

Identifying the root cause can sometimes help prevent future failures after you have completed the repair. 🛡️

II. The Essential Toolkit 🧰

You cannot perform microsurgery with regular mechanics’ tools. 🚫

Successful trace repair requires a specific set of high-quality tools. ✨

Here is what you should have on your bench before starting. 👇

- Precision Soldering Station: A generic, uncontrolled soldering iron will not cut it. You need a temperature-controlled station with a very fine conical or chisel tip (e.g., 0.2mm to 0.5mm). 🌡️

- Quality Flux: Flux is critical for ensuring solder flows onto the oxidized copper quickly without excessive heat. A tacky “no-clean” gel flux is often best for this work. 🍯

- Magnification: These traces are often thinner than a human hair. A good magnifying desk lamp (5x-10x) or, ideally, a stereo microscope is essential for seeing what you are doing. 🔬

- Jumper Wire: You need very fine, insulated copper wire. 30 AWG Kynar-insulated wire-wrap wire is the standard choice for most trace repairs. 🧵

- Scalpel or Hobby Knife: A brand new, extremely sharp #11 blade is necessary for scraping away the solder mask. 🔪

- Fiberglass Scratch Pen: This is excellent for gently abrading the surface to expose copper without cutting too deeply. 🖊️

III. Phase 1: Preparation and Inspection 🧐

90% of a good repair is in the preparation. ⏳

Rushing into soldering without properly preparing the area is a recipe for failure. ❌

A. Locating the Break 🔍

Sometimes the break is obvious to the naked eye, like a deep scratch across the board. 👀

Other times, it is a hairline fracture invisible without a microscope. 👻

The first step is to precisely locate the faulty area. 🎯

This is typically done using a high-quality digital multimeter set to continuity mode. 🔊

By probing the trace on known good points on either side of the suspected damage, you can confirm the issue. 📏

A lack of continuity beep (indicating an “open circuit” or OL) confirms the break exists between your probes. 🔇

https://youtu.be/2Ztzt68bA2s

B. Cleaning and Exposing the Trace 🧼

Once located, the area around the break must be meticulously cleaned of dust, grime, or old flux residues. 🧽

Use Isopropyl Alcohol (IPA) of 99% concentration and a lint-free cloth or brush. 💧

Next, you must remove the solder mask. 🎭

The solder mask is the protective polymer coating (usually green, blue, or red) that covers the copper traces. 🛡️

You must gently remove this layer to expose the bare, shiny copper trace on both sides of the break to create points for soldering. ✨

Be extremely careful during this step, as excessive force will cut right through the thin copper trace you are trying to save. ⚠️

Here are the common techniques for removing the mask. 👇

| Tool | Purpose | Technique |

|---|---|---|

| Fiberglass Brush (Scratch Pen) | Removing oxidation and light contaminants gently. | Use a gentle, circular scrubbing motion until copper appears. |

| Hobby Knife/Scalpel (#11 Blade) | Carefully scraping away thicker solder mask layers. | Hold the blade perpendicular to the trace and scrape lightly like a chisel. |

| Rotary Tool (Dremel) | For controlled removal over a larger damaged area. | Use a very fine abrasive bit at low RPM, held very lightly. High risk of damage. |

After scraping, give the area another quick clean with IPA to remove the debris generated by scraping. 🧹

IV. Phase 2: The Repair Techniques 👨🏭

The choice of repair technique depends significantly on the width of the trace and the severity of the damage. 📏

For most standard signal traces, one method stands above the rest for reliability. 🏆

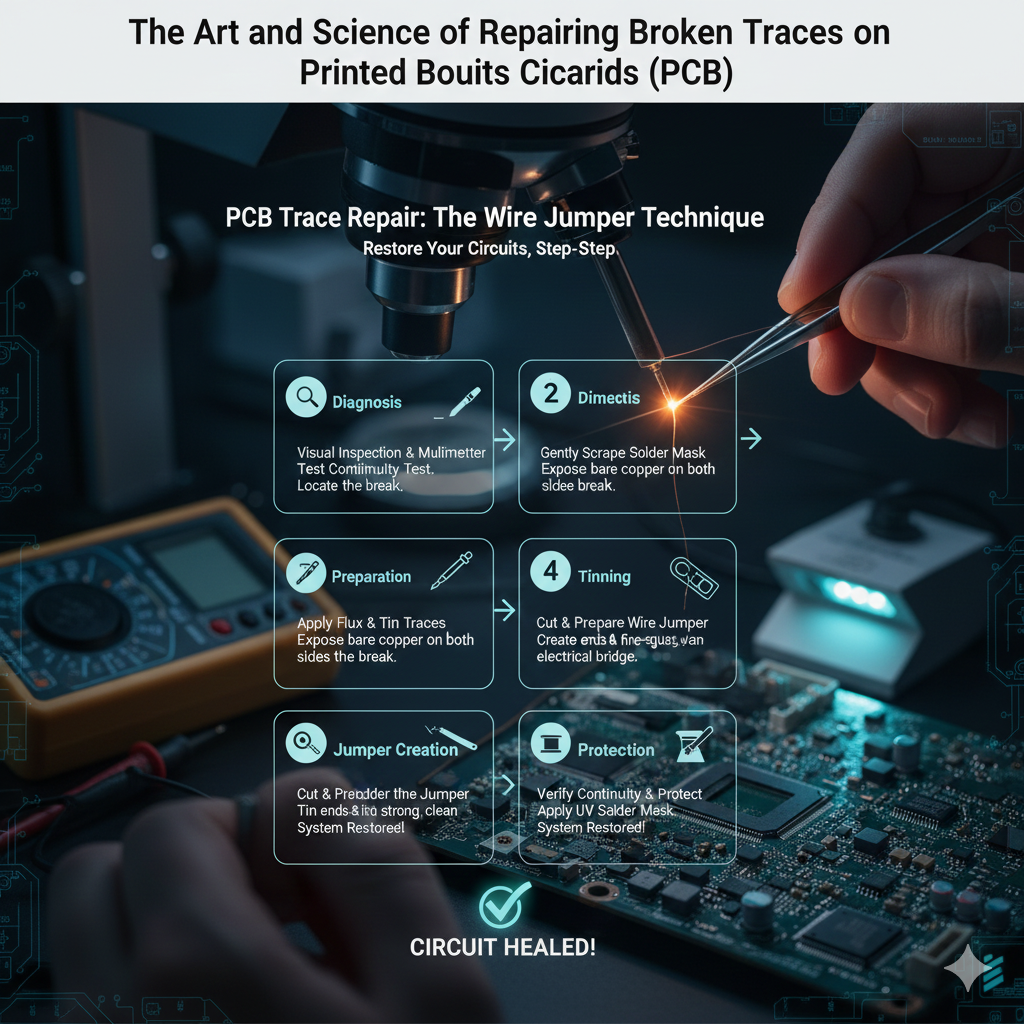

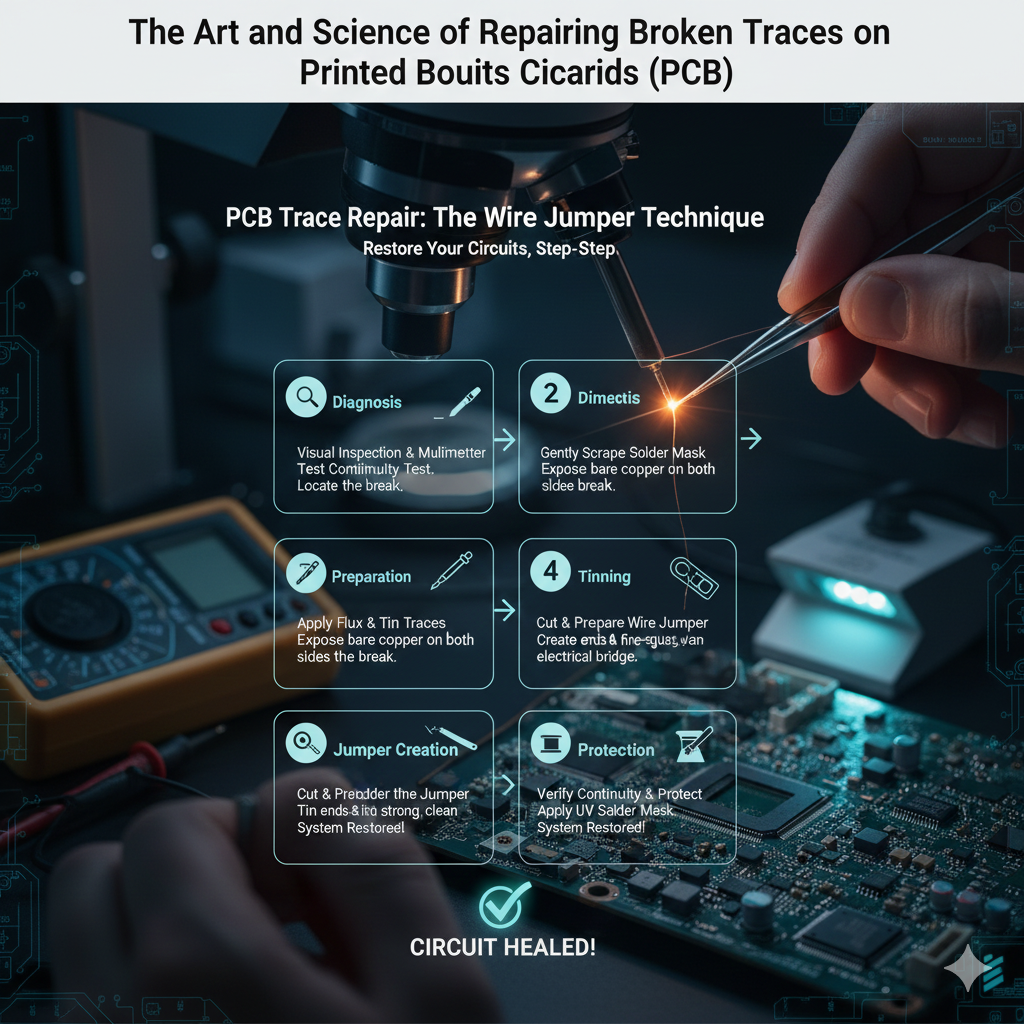

A. The Wire Jumper Method (The Gold Standard) 🥇

This technique involves bypassing the break entirely by soldering a fine, insulated wire across the damaged area to restore the electrical connection. 🔗

It is the most durable and professional way to fix a broken trace. 💪

For an excellent visual guide on this process, check out this resource from Chemtronics on PCB trace repair. 🌐

Step 1: Tinning the Exposed Trace ✨

Apply a generous amount of tacky flux to the bare copper you exposed on both sides of the break. 🍯

Take your soldering iron with a clean tip and apply a very small amount of solder to it. 🌡️

Gently touch the iron to the fluxed copper pads. 🔥

The solder should instantly flow and coat the copper, leaving a shiny, thin layer of tin. ✨

Do this for both sides of the break. ↔️

Step 2: Preparing the Jumper Wire 🧵

Take your 30 AWG insulated wire. 📏

Use precision wire strippers or a very careful touch with your scalpel to strip just 1mm to 2mm of insulation from the end. 🤏

You want just enough bare wire to make the solder connection, but not so much that it risks shorting out nearby pads. ⚡

It is often helpful to “pre-tin” the exposed end of the wire with a little flux and solder as well. ✨

Step 3: Soldering the First Joint 🔗

Place the tinned end of your jumper wire onto one of the tinned PCB trace pads. 📍

Use tweezers to hold it steady. 🤌

Bring your soldering iron tip in and touch the junction of the wire and the pad. 🔥

The pre-applied solder on both surfaces should reflow together almost instantly. ⏱️

Remove the iron while still holding the wire perfectly still for a second until the solder solidifies. 🧊

A good joint will look shiny and smooth, not dull or grainy. ✨

Step 4: Routing and Securing 🗺️

Route the wire neatly across the gap to the other side of the break. ➡️

Try to follow the original path of the trace if possible. 🛣️

Cut the wire to length, ensuring it reaches the second pad with a tiny bit of slack so it is not under tension. ✂️

Strip the insulation from this second end just like the first. 🤏

Step 5: Soldering the Second Joint and Testing 🔗

Solder the second end of the wire to the other side of the broken trace using the same technique. 👨🏭

Once complete, allow it to cool. 🧊

Grab your multimeter again in continuity mode. 🔊

Probe the two points you just connected (or component pads attached to those traces) to confirm you now have solid continuity across the repair. ✅

https://youtu.be/VxB7v6YdJBs

B. Alternative: Conductive Ink and Epoxy 🖊️

For extremely fine traces where soldering a wire is nearly impossible, or for low-current applications, there are alternatives. 🤷

Specialized conductive pens containing silver-loaded ink can be drawn across the break. ✍️

Similarly, conductive epoxy can be applied with a toothpick to bridge a gap. 🦷

While seemingly easier, these methods have significant drawbacks. 📉

They generally have higher resistance than a copper wire jumper. ⚡

They are also mechanically less robust and can crack again under vibration or thermal stress. 💔

They are best reserved for temporary fixes or very specific low-stress situations. 🩹

For more on different repair methods, Hackaday has a great article detailing five ways to repair broken PCB traces. 🌐

V. Phase 3: Post-Repair Protection 🛡️

Just because the electrical connection is restored doesn’t mean the job is finished. 🏁

The repaired area is now vulnerable exposed copper and a delicate wire. 😓

You must protect it to ensure longevity. ⏳

1. Final Cleaning 🧼

Use IPA and a soft brush to aggressively clean the entire repair area. 🧽

Flux residues become corrosive over time and can eat away at your new solder joints if left behind. 🧪

2. Applying Solder Mask 🎭

The best protection is to replace the solder mask you scraped away. ✅

Use a UV-curable solder mask repair paint (often sold in syringes). 💉

Apply a thin layer over the entire repair, including the exposed copper pads and the jumper wire itself. 🖌️

This seals out moisture and oxygen, preventing oxidation. 🔒

It also acts as a glue, securing the jumper wire to the board so it doesn’t vibrate loose. 🧱

3. Curing the Mask ☀️

Most repair masks require UV light to cure and harden. 💡

Hit the area with a UV flashlight for the time specified by the manufacturer (usually 30 seconds to a few minutes). ⏱️

Once cured, the repair should be tough and permanent. 💪

For engineers looking for a deep dive into industrial standards for these repairs, AllPCB provides an ultimate guide. 🌐

https://youtu.be/4YStn5cggYw

Conclusion 🏁

Repairing broken PCB traces is a highly valuable skill in the world of electronics. 🌎

It transforms a “broken” device back into a functional one. ♻️

By following these meticulous steps of preparation, precise soldering with jumper wires, and robust post-repair protection, you can achieve reliable, long-lasting results. 🤝

Take your time, use the right tools, and remember that patience is key when working at this scale. 🧘

Let’s look at some more general soldering guides. iFixit has a great general guide on soldering that applies here. Also, for professional standards, always refer to IPC standards for electronics assembly and repair.