Hey there, fellow electronics enthusiasts! Ever found yourself staring at a stubborn SMD component, wondering why your rework efforts aren’t quite hitting the mark?

You’re not alone.

SMD rework can be a delicate dance, and even the most seasoned pros encounter hiccups.

But don’t fret!

Today, we’re diving deep into the world of SMD rework troubleshooting, arming you with the knowledge to conquer common issues and achieve those pristine, reliable repairs.

Videos are added as random thoughts 💭 💭.

Understanding the Battlefield: Common SMD Rework Problems

Before we jump into solutions, let’s identify the common adversaries you might face.

Recognizing these issues is the first step towards effective troubleshooting.

1. The Elusive Connection: S-E and H-E Errors

If your hot air rework station is flashing ‘S-E’ or ‘H-E’, it’s trying to tell you something important.

‘S-E’ typically points to a Sensor Error.

This could be as simple as a loose connection or, in some cases, a failing heat sensor.

Sometimes, a little jiggling of the dial or re-seating the heater can magically make it disappear.

It’s often due to oxide buildup on connections, fooling the controller into thinking the heater has failed.

‘H-E’ signifies a Heating Error.

This usually means there’s an issue with the heating element itself, or it’s not properly connected.

Double-check those connections! If all else fails, a replacement heating element might be in order.

2. The Unruly Breeze: Low or Excessive Airflow

Low Airflow: If your ‘Air’ dial is cranked up but you’re barely feeling a whisper, ensure your nozzle is securely attached.

A proper nozzle connection is crucial for directing airflow effectively.

Excessive Airflow: On the flip side, too much air can turn your delicate SMD components into tiny projectiles.

We’ve all been there, watching a resistor take flight! Start with a lower airflow setting and gradually increase it as needed.

Precision, not power, is key here.

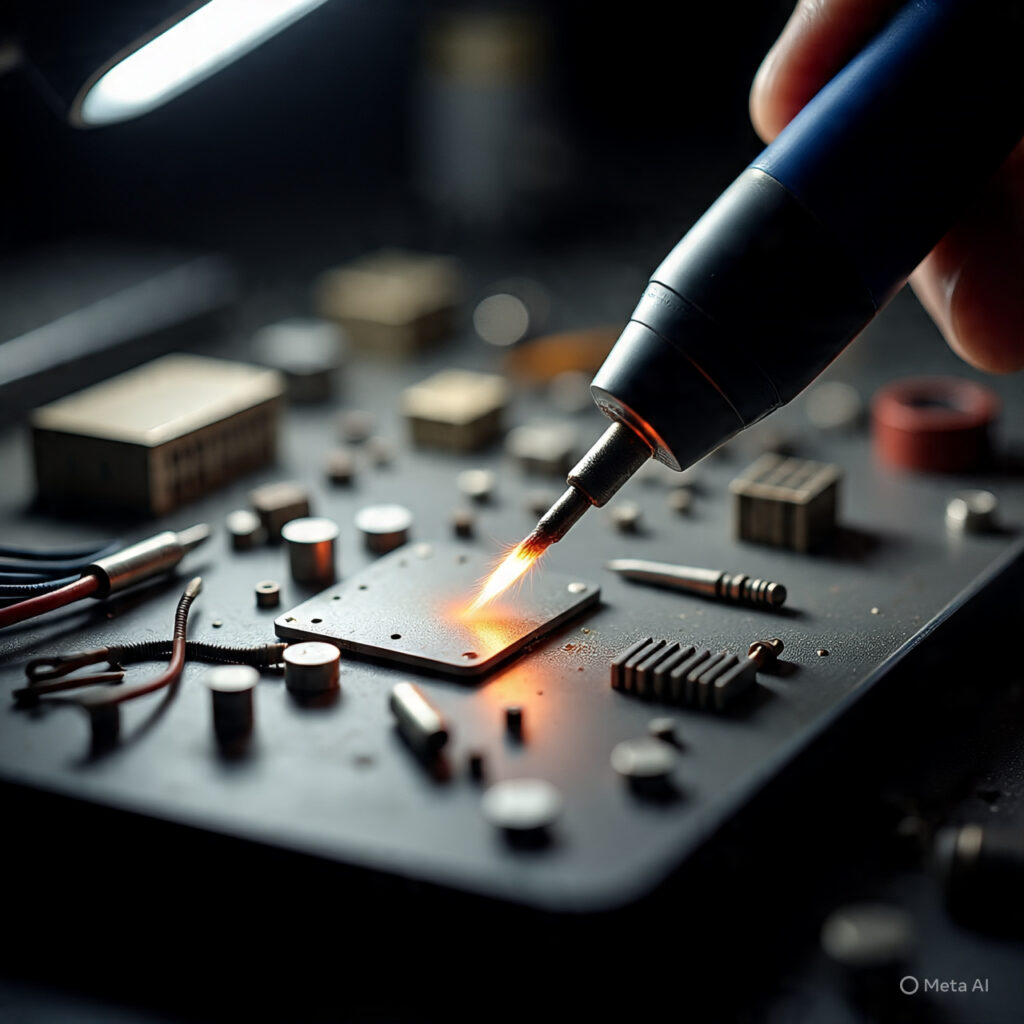

3. The Scorched Earth: Destroying a PCB

This is a painful one. Lingering too long with hot air on a single spot can cause the glue holding the copper layer to the FR4 laminate to break down, resulting in a nasty black goo.

The green soldermask might also start peeling off.

And the smell?

Oh, the smell! It’s a pungent reminder of a PCB’s last breath.

Practice makes perfect, and learning to move your hot air tool efficiently is vital to avoid this.

4. The Detached Pad: Pulled Pads

When you’re checking if a component is ready to be moved, a gentle nudge is all it takes.

Applying too much force can lead to a pulled pad,

which is a real headache to fix. Patience and a light touch are your best friends here.

Mastering the Art: Techniques and Best Practices

Now that we’ve identified the problems, let’s talk about how to prevent them and execute successful SMD reworks.

1. Temperature Control is King

Incorrect temperature settings are a common culprit for rework failures.

Always refer to the component’s datasheet for recommended soldering temperatures.

Preheating the PCB can also significantly improve your results, ensuring a more even heat distribution and reducing thermal stress on components.

2. Airflow: The Gentle Persuader

As mentioned, airflow control is critical.

Experiment with different nozzle sizes and airflow settings to find the sweet spot for each component.

The goal is to heat the solder evenly without blowing away components or overheating the board.

3. The Right Tools for the Job

Having the right equipment makes a world of difference.

A good quality hot air rework station with precise temperature and airflow control is essential.

Consider using preheaters for larger boards or sensitive components. Proper tweezers, flux, and solder paste are also non-negotiable.

4. Practice, Practice, Practice!

SMD rework is a skill that improves with experience.

Don’t be afraid to practice on old, discarded PCBs.

This will help you develop a feel for the right temperature, airflow, and timing.

Conclusion

SMD rework troubleshooting might seem daunting at first, but with a solid understanding of common issues and a commitment to best practices,

you’ll be performing flawless repairs in no time.

Remember, every failed attempt is a learning opportunity.

So, grab your tools, stay patient, and happy reworking!