The promise of Industry 4.0 —a fully digitized, interconnected, and intelligent manufacturing world—is rapidly becoming a reality.

This transformation, often encapsulated by the term Industrial Internet of Things (IIoT), is not driven by massive, centralized supercomputers, but by billions of tiny, specialized, and often overlooked components:

microcontrollers (MCUs). These small, powerful chips are the unsung heroes of the modern factory floor,

enabling the shift from reactive maintenance to proactive, predictive maintenance and turning conventional facilities into true smart factories.

The evolution of the IIoT is fundamentally an evolution of intelligence distribution.

Where early industrial automation relied on centralized Programmable Logic Controllers (PLCs) and Supervisory Control and Data Acquisition (SCADA) systems,

the modern smart factory pushes processing power right to the point of action. This is the realm of the microcontroller.

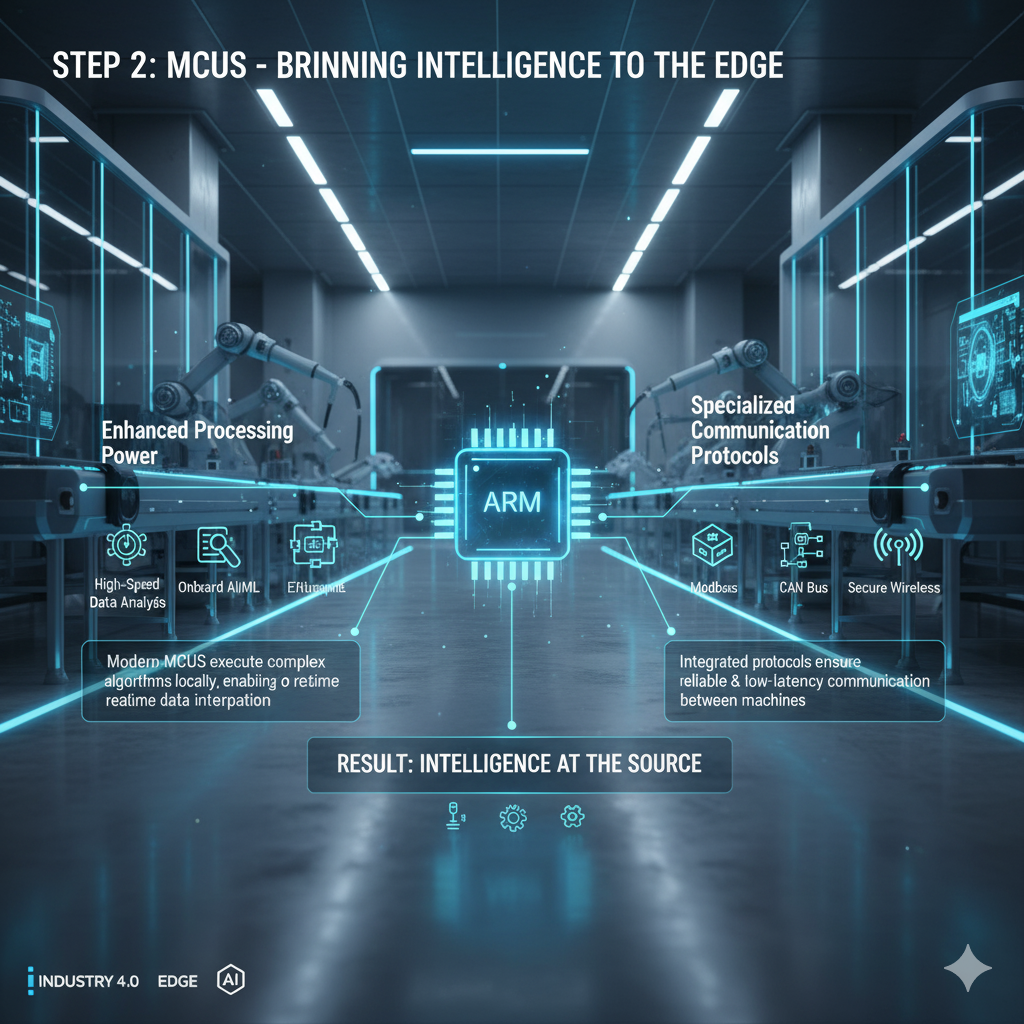

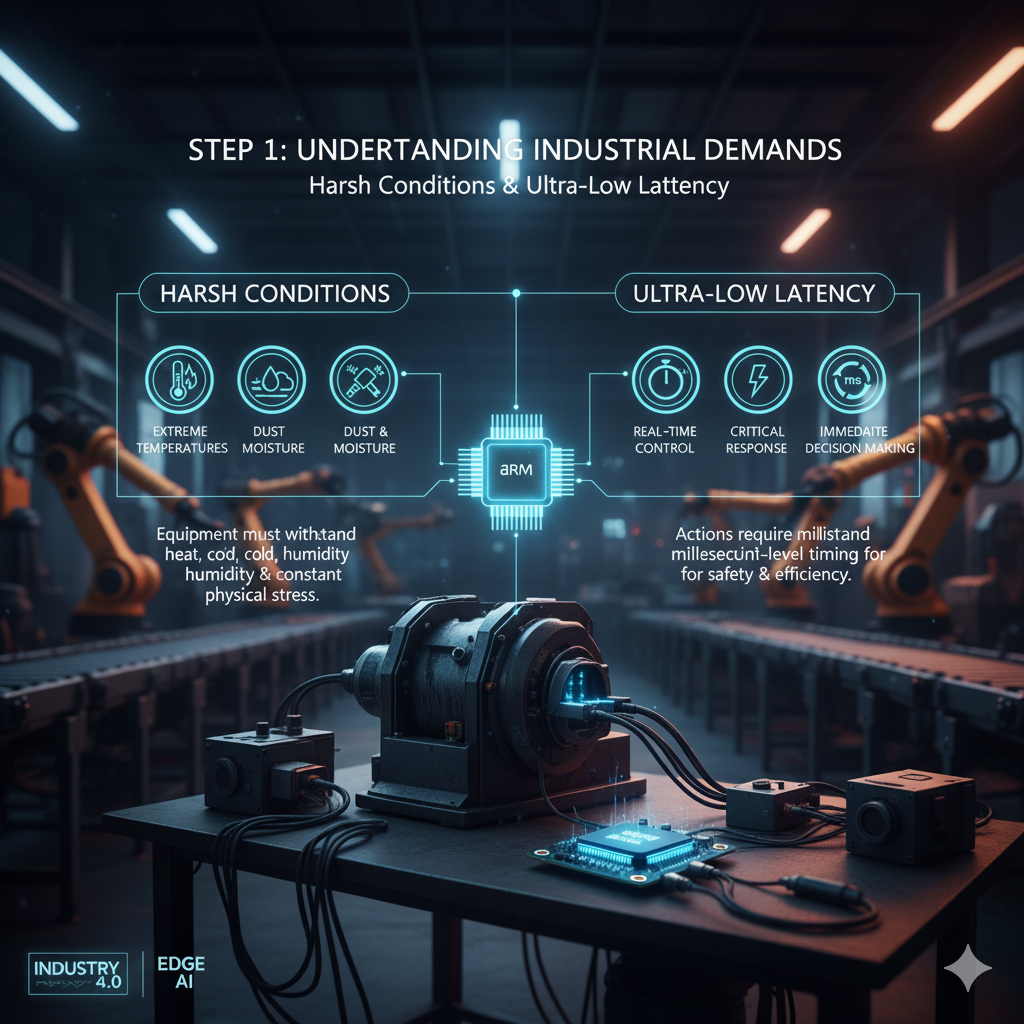

Beyond the Consumer: The Unique Demands of Industrial MCUs

When most people think of IoT, they picture smart thermostats or voice assistants.

The industrial environment, however, presents a set of challenges that demand a different class of technology.

Industrial MCUs are not merely faster or more powerful; they are engineered for a world of extremes.

1. Rugged Durability: Factory floors are harsh.

Industrial microcontrollers must operate reliably under conditions of extreme temperature fluctuations, high vibration, and significant electromagnetic interference (EMI).

They are often housed in robust enclosures,

but the chips themselves are designed with enhanced thermal and electrical tolerance that far exceeds consumer-grade components.

2. Specialized Communication: The industrial world speaks a different language. While consumer IoT relies heavily on Wi-Fi and Bluetooth, the IIoT demands ultra-reliable, low-latency communication over protocols like Modbus, Profibus, and Controller Area Networks (CAN).

Modern MCUs are equipped with native support for these interfaces, ensuring seamless integration with existing legacy machinery and real-time data exchange.

3. Ultra-Low Latency and Real-Time Operation:

In a manufacturing process, a delay of even a few milliseconds can lead to catastrophic failure, product defect, or safety hazards.

This is why many industrial MCUs utilize a Real-Time Operating System (RTOS).

An RTOS guarantees that critical tasks—like shutting down a machine when a proximity sensor is tripped or a temperature threshold is exceeded—are executed instantly and predictably, a necessity for safety and process control.

The Smart Factory: Interconnectivity and Data at the Edge

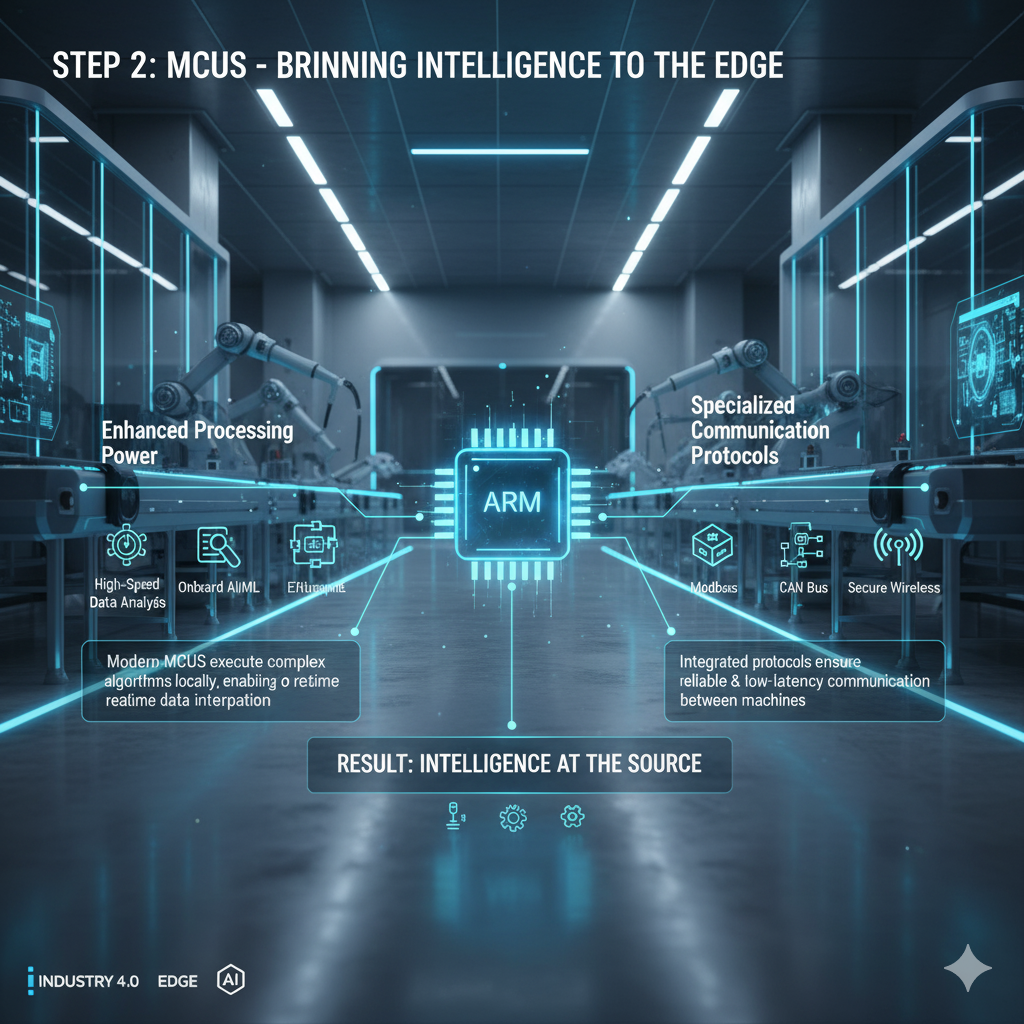

The Language of Industry: Specialized Communication Protocols

The seamless integration of microcontrollers into the existing industrial ecosystem is made possible by their mastery of specialized communication protocols.

While consumer IoT primarily uses IP-based networks, the factory floor requires protocols designed for reliability, real-time performance, and noise immunity.

Modbus and Profibus: These are the workhorses of industrial automation, providing a standardized way for devices to communicate with PLCs and SCADA systems.

Modern MCUs include hardware and software stacks to natively support these protocols, allowing them to act as intelligent gateways, translating raw sensor data into the language of the control system.

Controller Area Network (CAN): Originally developed for the automotive industry, CAN is widely used in industrial machinery for its robustness and deterministic nature.

It allows multiple devices to communicate reliably over a single bus, making it perfect for coordinating the sensors and actuators within a single complex machine, like a robotic arm or a CNC machine.

Time-Sensitive Networking (TSN): Representing the future of industrial communication, TSN is an enhancement to standard Ethernet that guarantees ultra-low latency and deterministic data delivery.

As IIoT systems scale, MCUs with TSN capabilities will become essential for mission-critical applications where timing is everything.

By supporting this diverse array of communication standards, microcontrollers ensure that the new, intelligent layer of the IIoT can coexist and enhance the decades-old infrastructure of the factory floor.

The concept of a smart factory hinges on complete interconnectivity, where every machine, every tool, and every component communicates its status in real-time.

Microcontrollers are the bridge that transforms raw physical phenomena into actionable digital data.

The concept of a smart factor hinges on complete interconnectivity, where every machine, every tool, and every component communicates its status in real-time.

Microcontrollers are the bridge that transforms raw physical phenomena into actionable digital data.

A modern factory might have hundreds of thousands of sensors:

vibration sensors on motors, temperature probes on furnaces, current sensors on robotic arms, and pressure gauges on hydraulic systems.

Each of these sensors is typically managed by a dedicated MCU.

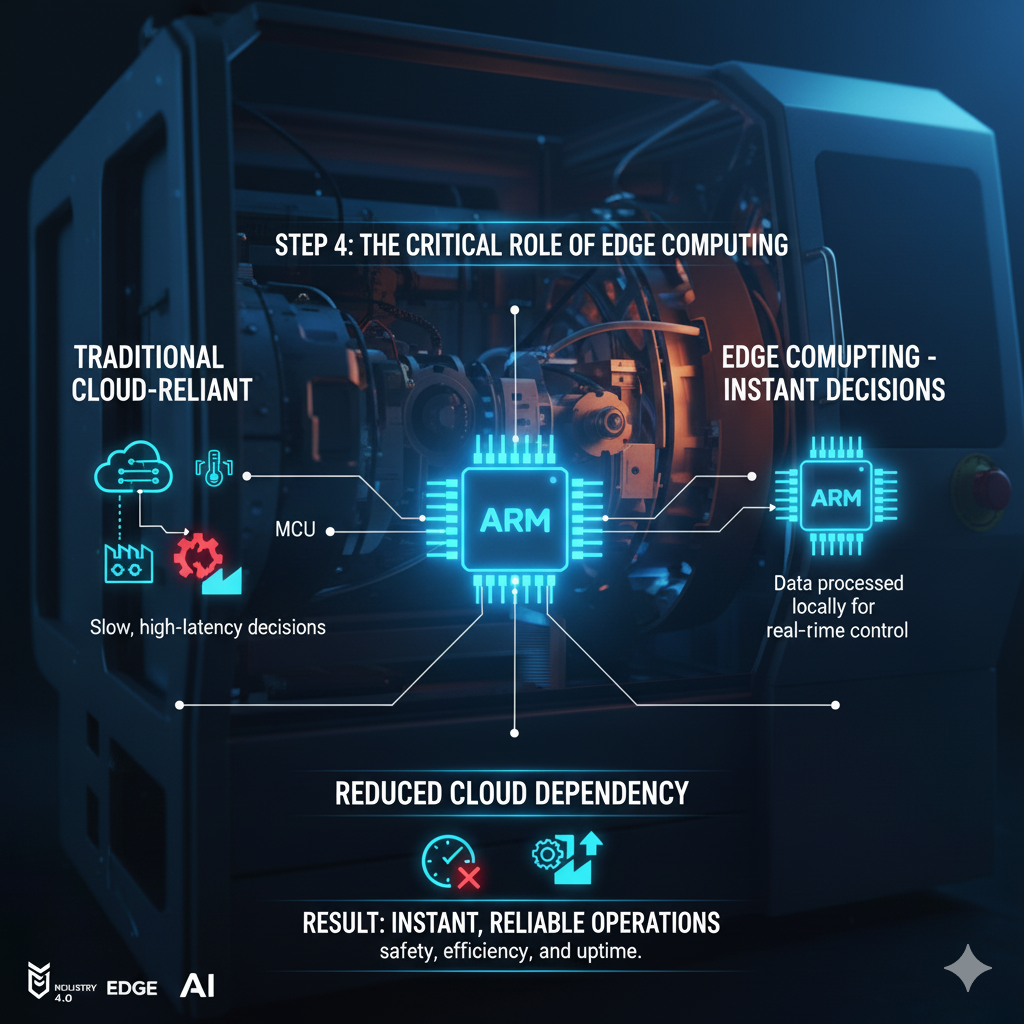

The Rise of Edge Computing

The sheer volume of data generated by a fully instrumented factory is staggering—terabytes per day in some cases.

Sending all of this raw data to the cloud for analysis is impractical, costly, and, most critically, too slow.

This is where edge computing comes into play, and the microcontroller is the primary edge device.

Instead of simply collecting data and forwarding it, the modern MCU performs pre-processing and analysis right at the source.

For example, a vibration sensor on a motor might generate thousands of data points per second.

The MCU can be programmed to:

1.Filter Noise: Remove electrical and mechanical interference from the raw signal.

2. Feature Extraction: Calculate key metrics like the Root Mean Square (RMS) or frequency spectrum of the vibration.

3. Anomaly Detection: Run a tiny, pre-trained Machine Learning (ML) model to determine if the current vibration pattern deviates from the “normal” baseline.

Only the result of this analysis—the “anomaly detected” flag or the calculated health score—is sent up the network, drastically reducing data transmission load and latency.

This local processing capability is what truly defines the “smart” in a smart factory.

Case Study in Action: The Bearing Failure That Never Happened

To illustrate the tangible impact of these tiny chips, consider a generalized scenario in a heavy manufacturing plant.

A critical asset, a large motor driving a conveyor belt, is essential for the entire production line.

Unplanned failure means hours of costly downtime.

The Old Way (Preventive Maintenance):

The motor bearings are replaced every 12 months, regardless of their actual condition.

Sometimes they fail at 10 months, causing an emergency shutdown.

Other times, the 12-month replacement discards a bearing with 6 months of life left.

The IIoT Way (Predictive Maintenance via MCU):

1. Installation: A small, rugged IIoT sensor module, powered by a high-performance MCU, is attached to the motor housing.

This module contains a tri-axial accelerometer and a temperature sensor.

2. Edge Intelligence: The MCU is programmed with a tiny ML model trained on historical vibration data. This model knows the “acoustic signature” of a healthy bearing versus one that is beginning to fail.

3. Real-Time Monitoring: The MCU continuously samples the vibration data at a high frequency (e.g., 25,000 samples per second).

It processes this data locally, running the ML inference model every few minutes.

4. Anomaly Detection: At the 15-month mark, the MCU detects a subtle, but statistically significant, increase in the vibration frequency associated with the outer race of the bearing.

The ML model’s confidence score for “impending failure” crosses the 85% threshold.

5. Actionable Alert: The MCU immediately sends a small, prioritized data packet via the factory’s Modbus network to the central maintenance system:

`ASSET_ID: MTR-45B, ALERT: Bearing Fail Imminent, CONFIDENCE: 88%, RECOMMENDED_ACTION:

Schedule Replacement (7-10 days)`.

The maintenance team receives the alert, orders the part, and schedules the replacement during the next planned, non-critical shutdown window.

The failure that would have stopped the entire line never happens.

This single intervention, enabled by the low-power, high-reliability processing of the microcontroller, pays for the entire IIoT deployment many times over.

This success story is replicated across countless industrial applications, from monitoring pressure in oil pipelines to tracking the health of wind turbine gearboxes.

The MCU is the indispensable component that makes this level of operational efficiency possible.

The Economic Imperative: ROI and the Future of Manufacturing Finance

The shift to an MCU-enabled IIoT infrastructure is not just a technical upgrade; it is a profound economic restructuring.

The Return on Investment (ROI) for predictive maintenance systems is often staggering,

making the adoption of smart factory technology an economic imperative rather than a luxury.

The primary financial benefits driven by the microcontroller’s edge capabilities include:

1. Dramatically Reduced Unplanned Downtime: The cost of an hour of downtime in a modern manufacturing plant can range from tens of thousands to millions of dollars.

By eliminating the majority of unplanned failures, MCUs directly protect revenue and production schedules.

2. Optimized Maintenance Spend: Switching from time-based (preventive) to condition-based (predictive) maintenance means technicians only intervene when necessary.

This reduces labor costs, minimizes the inventory of spare parts, and ensures that the full lifespan of every component is utilized.

3. Extended Asset Lifespan:

Continuous, granular monitoring allows for the early detection and correction of minor issues (e.g., slight misalignment) before they cause cascading damage.

This extends the operational life of expensive machinery, deferring capital expenditure.

4. Energy Efficiency and Process Optimization:

MCUs can monitor and control energy consumption at the device level, identifying and correcting inefficiencies in real-time.

This fine-grained control leads to significant reductions in operational energy costs.

These measurable financial gains solidify the microcontroller’s role as a core strategic asset in the modern enterprise.

The intelligent edge is not just about data; it’s about maximizing profitability and ensuring competitive advantage in a globalized market.

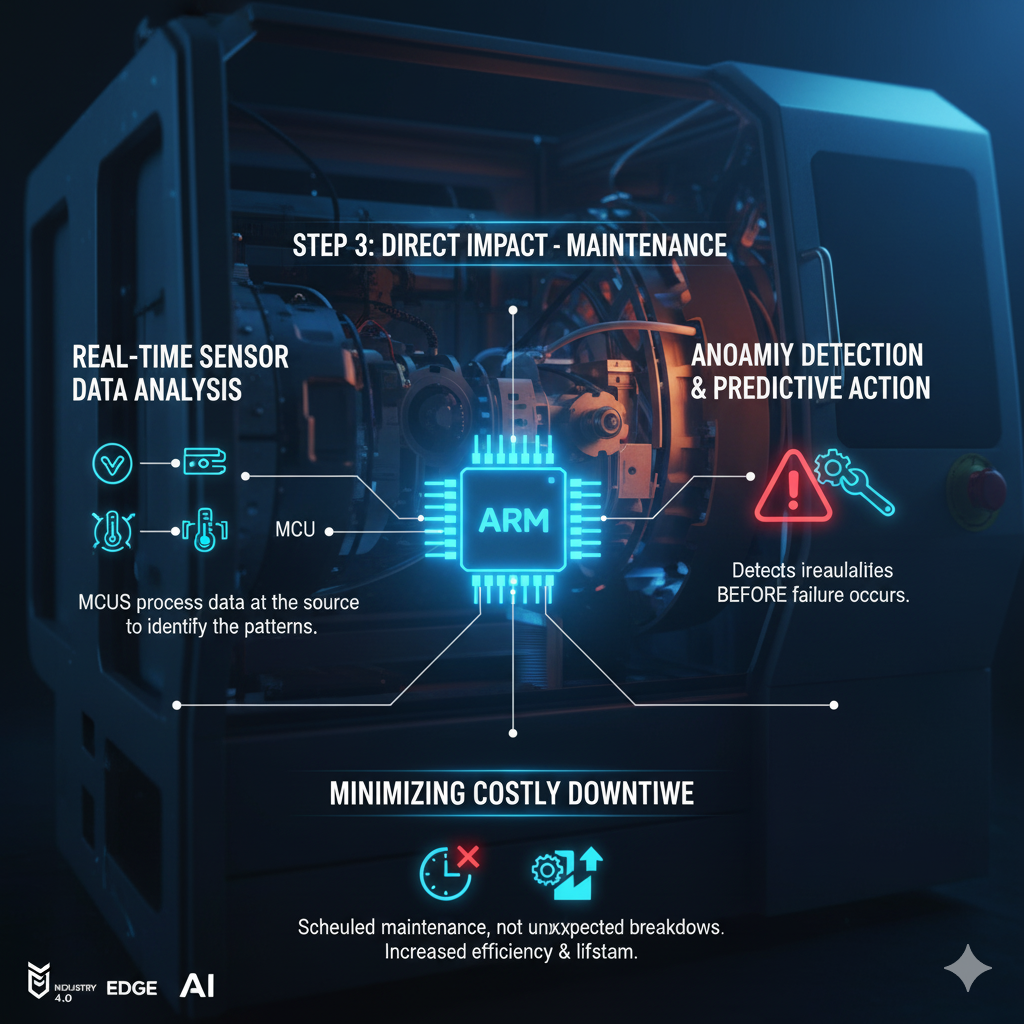

The Future: AI, Security, and Hyper-Integrationhe area where microcontrollers shine brightest, is predictive maintenance (PdM)

Historically, maintenance followed one of two models:

Reactive Maintenance (Breakdown Fix): Wait for a machine to fail, then fix it. This is costly, causes unplanned downtime, and can lead to secondary damage.

Preventive Maintenance (Time-Based): Replace parts on a fixed schedule (e.g., every 5,000 hours).

This is safer but inefficient, as perfectly good parts are often discarded.

Predictive maintenanceuses real-time data to determine the actual condition of assets, allowing maintenance to be scheduled only when it is truly needed, just before a failure is likely to occur.

The PdM Microcontroller Workflow

The MCU is the linchpin of the PdM system:

1. Data Acquisition: The MCU interfaces directly with the sensor (e.g., an accelerometer).

It converts the analog sensor signal into a digital stream.

2. Local Analysis (Edge AI): Using its internal processor, the MCU runs a sophisticated algorithm—often a form of Edge AI

—to look for the subtle signatures of impending failure, such as a shift in the motor’s vibration frequency indicating bearing wear.

3. Alert Generation: If the algorithm detects a high-risk pattern, the MCU immediately generates an alert, which is then transmitted to the factory’s central monitoring system or the cloud.

4. Action: The factory manager receives the alert, which states: “Motor X is showing signs of bearing failure (90% confidence).

Recommended maintenance window: next 7 days.” This allows for scheduled, efficient intervention.

This capability is revolutionary. By preventing unplanned downtime, companies can save millions in lost production and repair costs.

The shift from “fix it when it breaks” to “fix it before it breaks” is entirely dependent on the continuous, intelligent monitoring provided by the microcontroller.

The Future: AI, Security, and Hyper-Integration

The evolution of the IIoT is far from over. Future microcontrollers are focusing on three key areas:

1. Enhanced Edge AI: The trend is towards more powerful MCUs capable of running larger, more complex machine learning models directly on the chip.

This will allow for the detection of more nuanced and subtle failure modes, moving beyond simple threshold checks to true pattern recognition.

2. Hardware-Level Security: As factories become more interconnected, they become more vulnerable to cyber threats.

Modern industrial MCUs are integrating hardware-based security features, including secure boot, hardware encryption engines, and tamper-proof memory.

This ensures that the data collected at the edge is protected and that the device itself cannot be compromised to disrupt operations.

3. Hyper-Integration: Future MCUs will integrate more of the necessary components onto a single chip, including wireless transceivers (5G, LoRaWAN), power management units, and high-precision analog-to-digital converters (ADCs).

This hyper-integration reduces board space, lowers power consumption, and simplifies the design of rugged IIoT devices.

Conclusion

The evolution of Industrial IoT is a testament to the power of distributed intelligence.

The microcontroller, once a simple component for basic control, has transformed into a sophisticated, rugged, and intelligent edge processor.

By handling real-time data processing, enabling specialized communication, and powering the core logic of predictive maintenance, MCUs are not just participating in Industry 4.0

—they are the very foundation upon which the smart, efficient, and resilient factories of the future are being built.

The quiet revolution is here, and it’s running on a tiny chip.