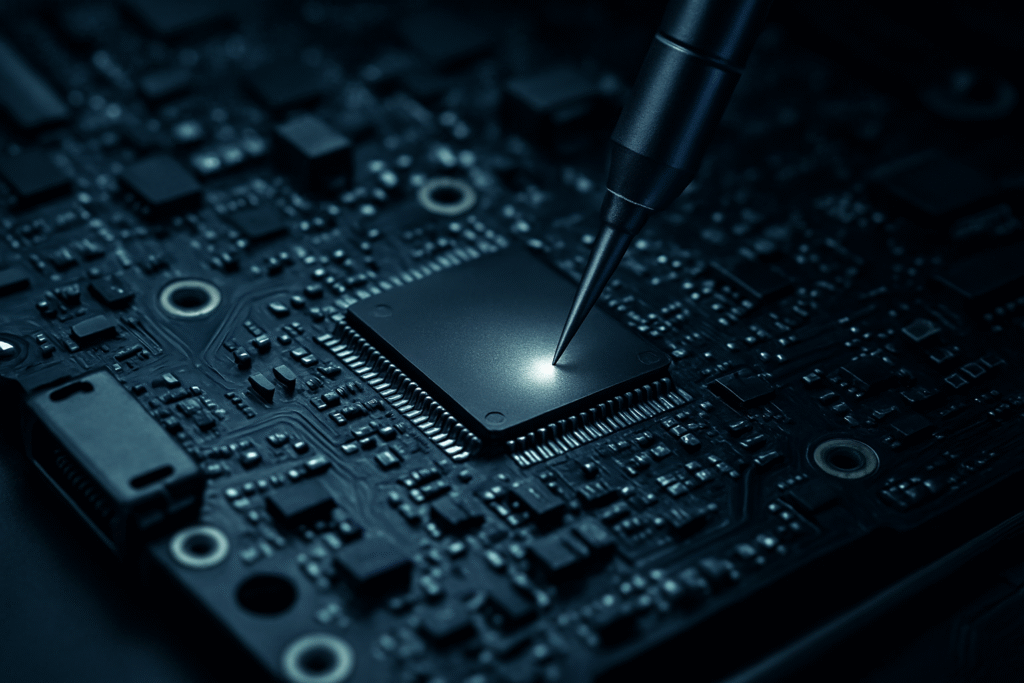

There’s a unique satisfaction in bringing a seemingly dead device back to life, especially when it involves the intricate dance of logic board repair.

For many, the thought of delving into the microscopic world of circuit boards can be daunting, often limited to basic soldering or component replacement.

But what if I told you there’s a whole universe of creative, advanced techniques that push the boundaries of what’s possible?

This isn’t about the everyday fixes; it’s about mastering the art of revival, transforming seemingly irreparable damage into a triumph of technical skill and ingenuity.

Join me as we explore the cutting-edge methods that elevate logic board repair from a simple fix to a true craft.

The Unseen Battlefield: Why Logic Boards Fail

Before we dive into the solutions, it’s crucial to understand the challenges.

Logic boards, the brains of our electronic devices, are incredibly complex.

They’re a dense tapestry of interconnected components, traces, and layers, all working in harmony.

But this complexity also makes them vulnerable.

Physical impacts, liquid spills, thermal stress from overheating, manufacturing defects, and even the subtle creep of tin whiskers can lead to catastrophic failures.

Diagnosing these issues often feels like detective work, requiring a keen eye, specialized tools, and a deep understanding of circuit behavior.

It’s a battlefield where microscopic damage can bring down an entire system, and traditional repair methods often fall short.

This is where creative thinking and advanced techniques become not just useful, but essential.

Videos are added as random thoughts 💭

Beyond the Soldering Iron: Advanced Micro-Soldering & Board Manipulation

When we talk about logic board repair, many immediately picture a soldering iron.

While essential, true mastery goes far beyond simply melting solder.

It involves a delicate blend of precision, patience, and specialized techniques that can seem almost surgical in their execution.

These methods allow us to tackle damage that was once considered terminal, breathing new life into devices others would deem irreparable.

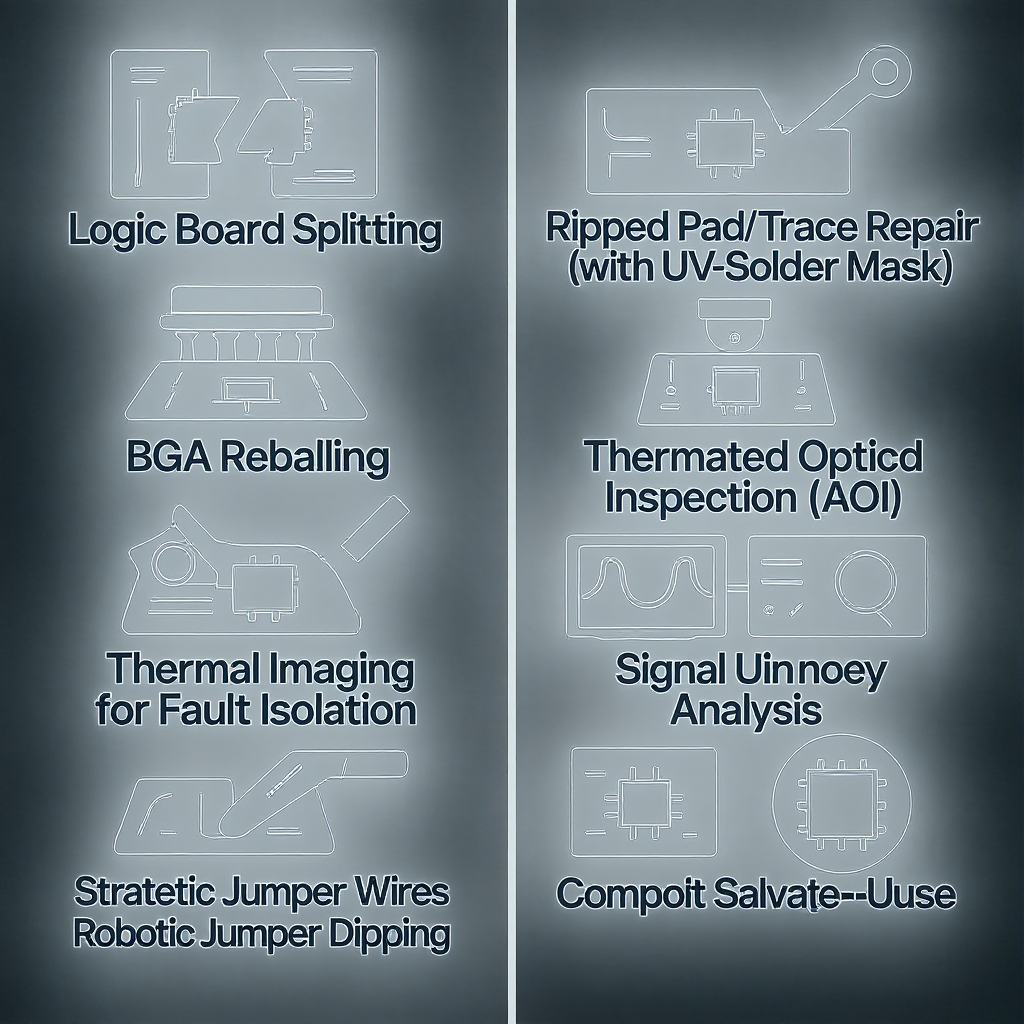

Logic Board Splitting & Reassembly

Imagine a multi-story building, but instead of floors, it’s layers of a circuit board, intricately connected.

Modern logic boards, especially in compact devices like smartphones, are often designed as ‘sandwich’ boards, with multiple PCBs stacked and interconnected.

When a fault lies deep within these layers, traditional repair is impossible.

This is where logic board splitting comes into play.

It’s a highly advanced technique that involves carefully separating these layers, often using controlled heat from specialized preheaters.

Once separated, the faulty component or damaged trace can be accessed and repaired.

The real challenge, and the true art, lies in the reassembly.

This requires meticulous alignment and precise reballing of the interposer—the connection layer between the boards—ensuring every microscopic solder ball makes perfect contact.

It’s a testament to skill, transforming a seemingly destroyed board into a functional unit once more.

Ripped Pad/Trace Repair with Solder Lugs & UV Solder Mask

Accidents happen, and sometimes, during a repair or due to physical trauma, a copper pad or trace on the logic board gets ripped or severed.

This can feel like a death sentence for the board.

However, creative repair specialists have developed ingenious methods to overcome this.

One such technique involves using solder lugs—tiny, pre-formed copper wires—to bridge the gap.

The process is painstaking: a microscopic wire is soldered to the remaining healthy trace, creating a new pathway.

But simply soldering isn’t enough; the new connection needs to be robust and insulated.

This is where UV solder mask, often affectionately called ‘The Green Stuff,’ becomes invaluable.

This liquid polymer is applied over the new connection and cured with ultraviolet light, creating a durable, insulating layer that secures the repair and prevents short circuits.

It’s a blend of artistry and engineering, restoring electrical continuity where it once seemed lost.

BGA Reballing: The Foundation of Revival

Ball Grid Array (BGA) components are ubiquitous on modern logic boards.

These chips, which include CPUs, GPUs, and memory, are connected to the board not by pins, but by an array of solder balls underneath.

Over time, or due to thermal stress, these solder balls can crack, leading to intermittent or complete failure.

BGA reballing is the process of removing the faulty component, cleaning off the old solder, and applying new, perfectly spherical solder balls using a specialized stencil.

The component is then carefully re-heated, allowing the new solder balls to melt and form fresh, reliable connections.

This technique is fundamental to repairing many common logic board issues, from unresponsive devices to graphical glitches, and it requires absolute precision to ensure every single ball makes proper contact.

The Sherlock Holmes of Circuits: Advanced Diagnostics & Rework Strategies

Beyond the physical act of repair, the true genius in logic board work lies in diagnosis.

It’s about understanding the subtle clues a malfunctioning board presents and employing sophisticated techniques to pinpoint the exact source of the problem.

This is where the repair technician transforms into a detective, using advanced tools and methodologies to unravel complex electronic mysteries.

Automated Optical Inspection (AOI)

In the realm of modern electronics manufacturing and repair, the human eye, even aided by a microscope, has its limits.

This is where Automated Optical Inspection (AOI) systems become indispensable.

These high-tech machines use sophisticated cameras and algorithms to rapidly scan circuit boards,

identifying defects such as missing components,

incorrect part placement, solder bridges,

and even subtle hairline cracks in traces that are invisible to the naked eye.

For a repair professional, an AOI system can drastically reduce diagnostic time and improve the accuracy of repairs, ensuring that no hidden fault goes undetected.

It’s like having a super-powered magnifying glass that can see through the noise and highlight the precise location of a problem.

Thermal Imaging for Fault Isolation

One of the most insidious problems in electronics is a short circuit, which can cause components to overheat or prevent a device from powering on.

Pinpointing the exact location of a short on a dense logic board can be incredibly challenging.

This is where thermal imaging shines.

By using an infrared camera, repair technicians can visualize the heat signatures across the board.

When a short circuit occurs, the current flows through the path of least resistance, causing a localized increase in temperature.

A thermal camera instantly reveals these hot spots, allowing the technician to precisely identify the faulty component or the exact location of the short, even if it’s buried under other components.

It’s a non-invasive, highly effective method for fault isolation that saves countless hours of tedious troubleshooting.

Signal Integrity Analysis

In high-speed digital circuits, it’s not enough for a trace to simply have continuity.

The quality of the electrical signal traveling along that trace, known as signal integrity, is paramount.

Issues like impedance mismatches, reflections, and crosstalk can corrupt data, leading to erratic behavior or complete system failure, even if the trace appears physically intact.

Advanced repair involves using tools like oscilloscopes and network analyzers to perform signal integrity analysis.

This allows technicians to examine the waveforms of signals, identify distortions, and diagnose subtle issues that might be caused by a damaged trace, a faulty component, or even an improperly repaired area.

It’s a deep dive into the electrical characteristics of the board,

ensuring that not only is the circuit complete, but it’s also functioning optimally.

Component-Level Modification

Sometimes, a repair isn’t just about replacing a faulty part; it’s about adapting or enhancing the existing circuit.

Component-level modification involves altering the functionality of a board by adding, removing,

or changing specific components to achieve a desired outcome or to bypass a persistent issue.

This could range from modifying power delivery circuits to improve stability,

to adding pull-up/pull-down resistors to correct signal levels,

or even implementing small circuit additions to restore functionality when original parts are unavailable.

It requires a profound understanding of electronics principles and circuit design, transforming a repair technician into a circuit architect.

The Contrast Method: Repairing Without Schematics

Imagine trying to fix a complex machine without a blueprint.

That’s often the challenge in logic board repair, especially for proprietary or older devices where schematics are unavailable.

The contrast method is an ingenious, albeit labor-intensive, technique for diagnosing faults without schematics.

It involves comparing the electrical characteristics of a faulty board to a known good board, often using a multimeter or an oscilloscope in comparative mode.

By systematically probing various points on both boards and noting discrepancies in voltage, resistance, or signal waveforms, a skilled technician can identify anomalies that point to the location of the fault.

It’s a testament to observational skill and pattern recognition, allowing repairs to proceed even in the absence of official documentation.

The Maverick’s Toolkit: Unconventional Approaches

While precision micro-soldering and advanced diagnostics form the bedrock of creative logic board repair, some techniques push the boundaries even further, venturing into what might be considered unconventional.

These methods often arise from necessity, ingenuity, and a deep understanding of the underlying principles of electronics, allowing for repairs that defy traditional expectations.

Strategic Jumper Wires

At first glance, a jumper wire might seem like the most basic of repairs—a simple wire connecting two points.

However, in the context of advanced logic board repair, the strategic use of jumper wires is far from basic.

When internal traces are damaged beyond direct repair, or when a complex multi-layered board makes trace repair impractical, a precisely routed and insulated jumper wire can bypass the damaged section.

This isn’t about haphazardly running wires; it involves careful planning to avoid interference, minimize signal degradation, and ensure mechanical stability.

The wire itself might be hair-thin, requiring extreme dexterity to solder under a microscope.

When executed with precision, these jumpers become an invisible,

yet vital, part of the circuit, restoring functionality without compromising the board’s integrity.

It’s a testament to the idea that sometimes, the simplest solution, applied with expert skill, can be the most elegant.

Robotic Hot Solder Dipping (RHSD)

As electronics become more complex and miniaturized, the demand for consistent and high-quality component preparation increases.

Robotic Hot Solder Dipping (RHSD) is an advanced technique primarily used for component tinning and gold mitigation.

Many components, especially older or specialized ones, might have leads that are oxidized or plated with materials like gold, which can lead to brittle solder joints (gold embrittlement).

RHSD involves using robotic precision to dip component leads into a molten solder bath,

ensuring a perfectly tinned, consistent, and reliable surface for soldering onto the logic board.

This automated process minimizes human error, ensures uniform solder thickness, and is particularly valuable for preparing components for reballing or for use in high-reliability applications.

It’s a behind-the-scenes hero in the repair world, ensuring that the components themselves are in optimal condition before they even touch the logic board.

Component Salvage & Reuse

In an era of increasing electronic waste and planned obsolescence, component salvage and reuse is not just an unconventional repair technique, but also a sustainable practice.

Instead of simply discarding a dead logic board, skilled technicians can meticulously desolder and reclaim functional, often rare or expensive, components from it.

This requires specialized tools and techniques to ensure the components are removed without damage and are still within their operational specifications.

These salvaged components can then be used to repair other boards, especially those for which new parts are no longer manufactured or are prohibitively expensive.

This approach not only reduces waste but also provides a vital supply chain for legacy device repair, extending the lifespan of electronics and challenging the throwaway culture.

It’s a circular economy in action, driven by the hands of a skilled repair professional.

The Future of Repair: Innovation and Sustainability

The world of logic board repair is constantly evolving, driven by the ever-increasing complexity of electronic devices and a growing demand for sustainable practices.

The techniques we’ve explored—from splitting multi-layered boards to employing thermal imaging and salvaging components—represent a frontier where innovation meets necessity.

As technology advances, so too will the methods for repairing it.

The future of repair lies not just in fixing what’s broken, but in understanding the intricate dance of electrons, the subtle whispers of faulty components, and the creative application of advanced tools and knowledge.

It’s a field that demands continuous learning, a passion for problem-solving, and a commitment to extending the life of our precious electronics.

Conclusion: Mastering the Microcosm

Logic board repair is far more than just a technical skill; it’s an art form, a science, and a testament to human ingenuity.

Moving beyond the basics opens up a world of possibilities, allowing us to tackle challenges that once seemed insurmountable.

Whether it’s meticulously reballing a BGA chip, precisely repairing a ripped trace with UV solder mask,

or strategically bypassing a damaged internal layer with a hair-thin jumper wire,

each technique is a step towards mastering the microcosm of modern electronics.

So, the next time you encounter a seemingly dead device, remember that with the right knowledge, tools, and a creative mindset, revival is always within reach.

Embrace the challenge, hone your skills, and become a true artisan of logic board repair.